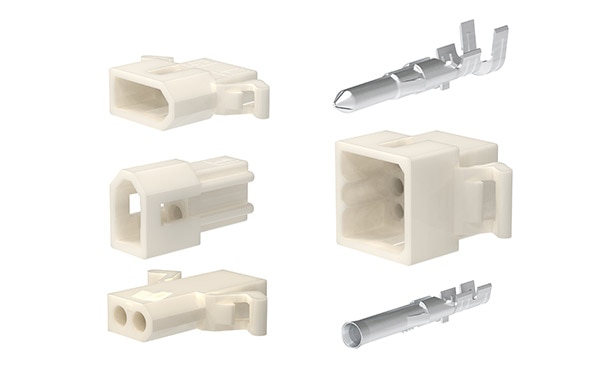

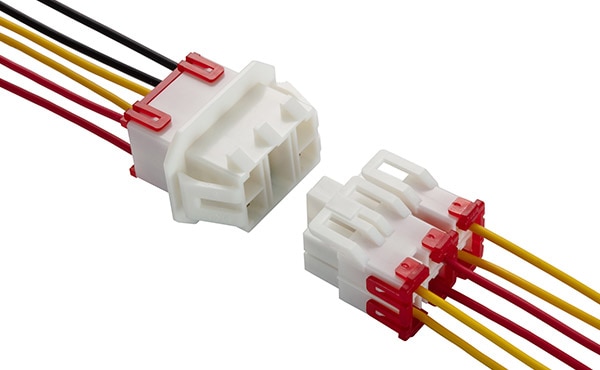

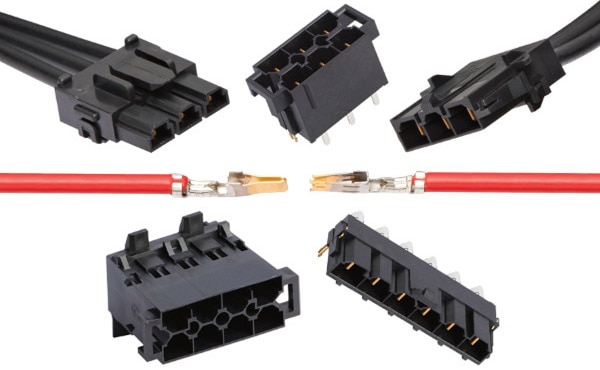

Mini50 Power Connector

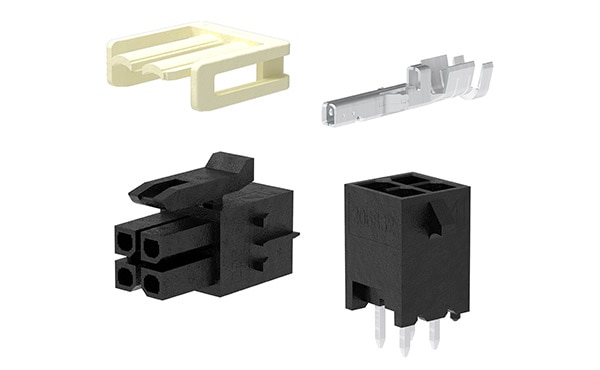

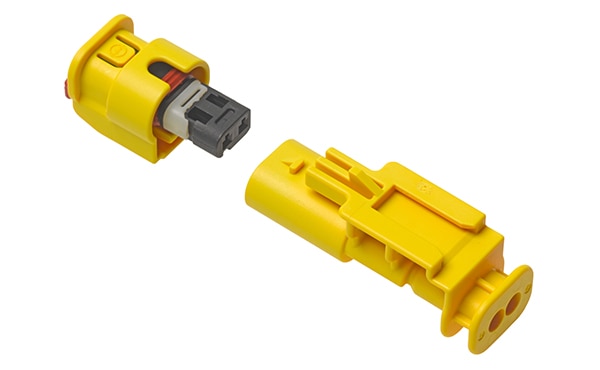

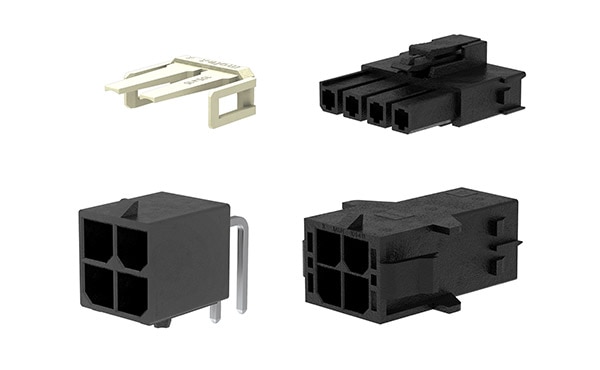

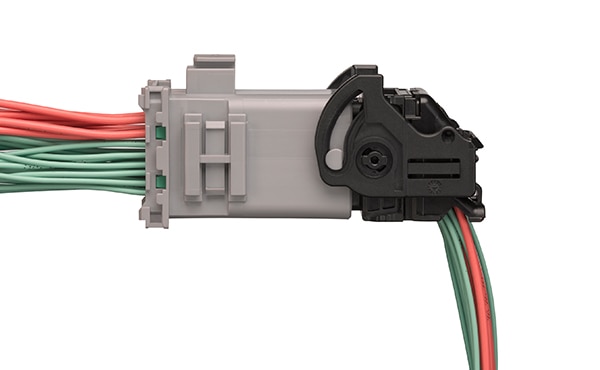

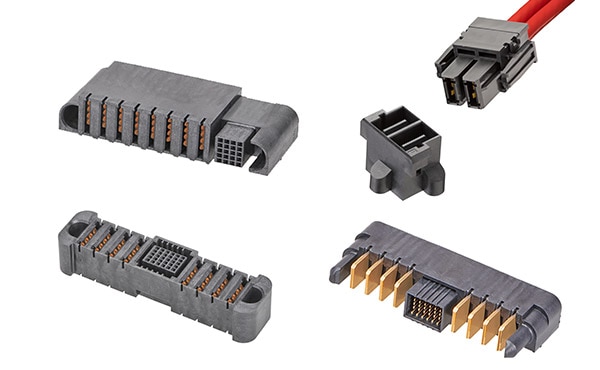

The Molex Mini50 Gen II Unsealed Connectors provide improved reliability with features such as a 4-sided cavity for better terminal alignment and increased primary lock retention, a hinged independent secondary lock (ISL), reduced misalignment angles and better scoop proofing, along with an improved connector position assurance (CPA) design.

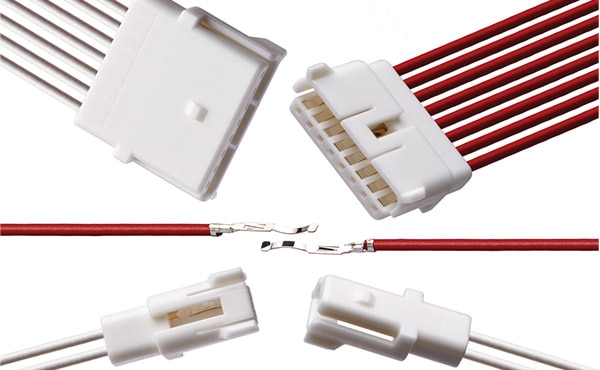

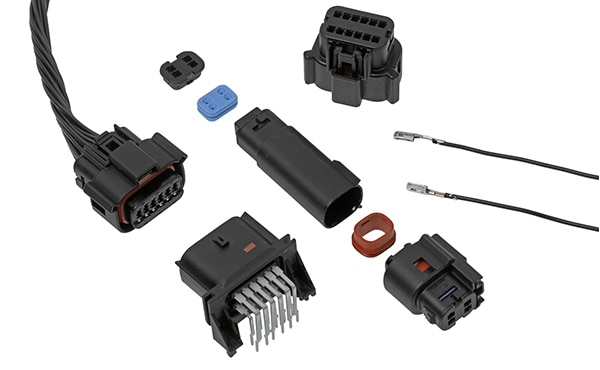

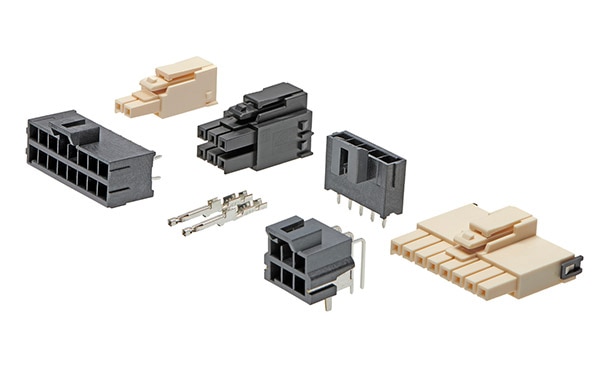

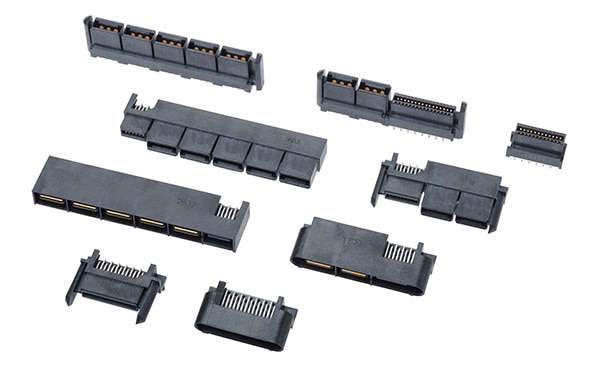

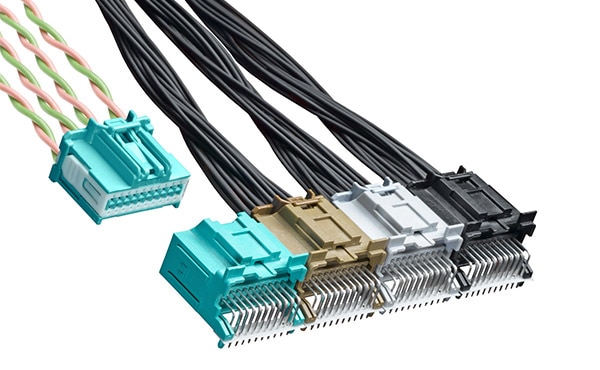

Conector Type: Sealed and Unsealed

Circuits: 4 - 38

Additional Options: 50% smaller vs 0.64 mm USCAR