Selecting the Appropriate Heat Shrink Tubing

Contributed By DigiKey

2018-01-15

Heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used for the insulation and corrosion protection of various wiring harnesses, solder joints and components. It is also excellent for minor repairs of cables and connectors. However, before selecting the appropriate heat shrink tubing for a specific application, it is vital to understand the characteristics and the key parameters of this product.

Figure 1: Heat shrink tubing can protect the terminal area from contamination and can identify wiring with a color code.

Figure 2: Heat shrink tubing can be used to repair damaged wires and cables.

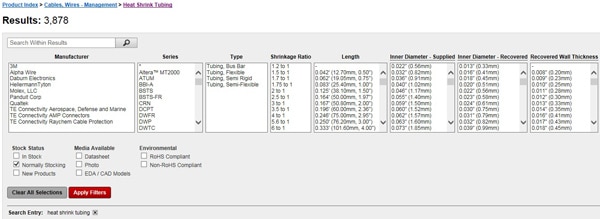

There are various sizes of heat shrink tubing available on the market, so how do you select the most appropriate product? By making an informed decision utilizing the various parametric options for heat shrink tubing on the DigiKey website.

Figure 3: Some of the various parametric options for heat shrink tubing.

Parameter 1: Inner Diameter

In order to determine an appropriate inner diameter, both the maximum and minimum perimeter of the object to be covered with the tubing need to be known. For the maximum perimeter, selecting an appropriate tubing ‘supplied’ inner diameter with an additional 20 - 30% allowance will provide adequate space for the heat shrink tubing to fit over any anomalous protrusions. For the minimum perimeter, selecting a smaller tubing ‘recovered’ inner diameter ensures the tubing will adequately shrink and tightly envelop the object.

Figure 4: Heat shrink tubing with various supplied inner diameters, types and colors.

The “Inner Diameter - Supplied” parameter and the “Inner Diameter - Recovered” parameter definitions are as follows:

- Inner Diameter - Supplied: The minimum inner diameter of the heat shrink tubing offered by the manufacturer before it is heated.

- Inner Diameter - Recovered: The minimum inner diameter of the heat shrink tubing after it is heated.

Figure 5: Shrinkage ratio, length, inner diameter, and recovered wall thickness parameters.

Parameter 2: Shrinkage Ratio

The “Shrinkage Ratio” parameter is also useful in selecting the appropriate heat shrink tubing. Several shrinkage ratio options for the tubing are available such as 1.2 to 1, 1.5 to 1, etc.

![]()

A high shrinkage ratio means that the heat shrink tubing is more suitable for objects like connectors as it can encase the connector body and still be able to shrink down to a smaller diameter such as a wire or cable. In general, it is recommended that the supplied inner diameter of the heat shrink tubing and the size of the object to be protected should not exceed a 40% ratio to allow for effective coverage.

Parameter 3: Length

It should be noted that heat shrink tubing also shrinks longitudinally by 5 - 7% when it is heated. Therefore, adjustments should be made when selecting the length.

Parameter 4: Recovered Wall Thickness

Heat shrink tubing is available in various recovered wall thicknesses. When selecting this parameter, the application and environment should be considered.

Other parameters: Material, working temperature and shrinkage temperature

The material heat shrink tubing is made from denotes its features. For example, PTFE (polytetrafluoroethylene) tubing is characterized by resistance to flame and chemicals, and has an operating temperature of 260˚C.

Figure 6: Material, features, working temperature, and shrinkage temperature parameters.

Summary

In summary, the following elements should be taken into careful consideration when selecting the appropriate heat shrink tubing:

- The size of the object to be encased in order to determine the tubing inner diameter, shrinkage ratio, and length.

- The application and environment to determine an appropriate recovered wall thickness.

- The tubing material, features, operating temperature, and shrinkage temperature to determine overall compatibility with the application.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.