How to Simplify Motor Drive and Inverter Designs Using IGBT Modules

Contributed By DigiKey's North American Editors

2020-12-10

The use of motors and inverters continues to grow across applications such as industrial automation, robotics, electric vehicles, solar energy, white goods, and power tools. Along with this growth is the need to improve efficiency, lower cost, shrink footprint and simplify the overall design. While it’s tempting to design custom motor and inverter power electronics using discrete insulated gate bipolar transistors (IGBTs) to fit specific requirements, this can be costly in the long term and delay design schedules.

Instead, designers can use off-the-shelf IGBT modules which combine multiple power devices into a single package. Such modules support designers’ need to develop compact systems with a minimum of interconnects, thereby simplifying assembly, reducing time-to-market and cost, and improving overall performance. Combined with an appropriate IGBT driver, IGBT modules enable the development of efficient and cost effective motor drives and inverters.

This article briefly describes electric motors and inverters and the associated drive circuits and performance requirements. It will then review the benefits of using IGBT modules and various module packaging standards before introducing motor drive and inverter design options based on IGBT modules and driver ICs from vendors such as NXP Semiconductors, Infineon Technologies, Texas Instruments, STMicroelectronics, and ON Semiconductor, and how to apply them, including the use of evaluation boards.

Motor types and efficiency standards

IEC/EN 60034-30 divides motor efficiency into 5 classes IE1 to IE5. The National Electrical Manufacturers Association (NEMA) has a corresponding ratings scale from ‘standard efficiency’ to ‘ultra-premium’ efficiency (Figure 1). The use of electronic drives is necessary to meet the higher efficiency standards. AC induction motors with electronic drives can meet IE3 and IE4 requirements. Costlier permanent magnetic motors and electronic drives are needed to meet IE5 efficiency levels.

Figure 1: Motor efficiency classes according to IEC/EN 60034-30 (IE1 to IE5) and corresponding NEMA ratings (standard efficiency to ultra-premium efficiency). AC induction motors with FOC and electronic drives can meet IE3 and IE4 requirements. Permanent magnetic motors are needed to meet IE5 efficiency levels. (Image source: ECN)

Figure 1: Motor efficiency classes according to IEC/EN 60034-30 (IE1 to IE5) and corresponding NEMA ratings (standard efficiency to ultra-premium efficiency). AC induction motors with FOC and electronic drives can meet IE3 and IE4 requirements. Permanent magnetic motors are needed to meet IE5 efficiency levels. (Image source: ECN)

The development of low-cost microcontrollers (MCUs) has enabled designers to use vector control, also called field-oriented control (FOC), a variable-frequency drive (VFD) control method in which the stator currents of a three-phase AC motor are identified as two orthogonal components that can be visualized with a vector. Proportional-integral (PI) controllers can be used to keep the measured current components at their desired values. The pulse-width modulation of the VFD defines the transistor switching according to the stator voltage references that are the output of the PI current controllers.

Originally developed for high-performance systems, FOC is becoming increasingly attractive for lower cost applications as well due to FOC's motor size, lower cost and lower power consumption. Due to the growing availability of low-cost high-performance MCUs, FOC is increasingly displacing lower performance single-variable scalar volts-per-Hertz (V/f) control.

There are two primary types of permanent magnet motors in use today, brushless DC (BLDC) and permanent magnet synchronous motors (PMSM). Both of these advanced motor designs require power electronics for drive and control.

BLDC motors are durable, efficient and cost effective. PMSM motors have the attributes of BLDC motors with lower noise and somewhat higher efficiencies. Both types of motors are commonly used with Hall sensors but can also be used in sensorless designs. PMSM motors are used in applications that require the highest levels of performance, while BLDC motors are used in more cost sensitive designs.

- BLDC Motors

- Easier to control (6 Step) and only DC currents required

- Torque ripple at commutations

- Lower cost and lower performance (compared with PMSM)

- PMSM Motors

- Commonly used in servo drives with an integrated shaft encoder

- More complex control (needs 3-phase sinusoidal PWM)

- No torque ripple at commutation

- Higher efficiency, higher torque

- Higher cost and higher performance (compared with BLDC)

Inverter overview

The efficiency of an inverter indicates how much DC input power is converted to AC power on the output. High quality sine wave inverters deliver 90-95% efficiency. Lower quality modified sine wave inverters are simpler, less expensive and less efficient, typically 75-85%. High-frequency inverters are usually more efficient than low-frequency designs. Inverter efficiency also depends on inverter load (Figure 2). All inverters require power electronic drives and controls.

In the case of photovoltaic inverters, there are three types of efficiency rankings:

- Peak efficiency indicates the performance of the inverter at the optimal power output. It shows the maximum point for a particular inverter and can be used as a criterion of its quality (Figure 2).

- European efficiency is the weighted number taking into account how often the inverter will operate at different power outputs. It is sometimes more useful than peak efficiency as it shows how the inverter performs at different output levels during a solar day.

- California Energy Commission (CEC) efficiency is also a weighed efficiency, similar to the European efficiency, but it uses different assumptions on weighting factors.

The main difference between the European and CEC efficiencies is that the assumptions about the importance of each power level for a particular inverter are based on the data for Central Europe in the former case, and California in the latter.

Figure 2: Typical inverter efficiency curve showing the point of peak efficiency. (Image source: Penn State University)

Figure 2: Typical inverter efficiency curve showing the point of peak efficiency. (Image source: Penn State University)

IGBT basics

The basic function of an IGBT is the fastest possible switching of electric currents with the lowest possible losses. As the name indicates, an IGBT is a bipolar transistor with an isolated gate structure; the gate itself is basically a MOSFET. Therefore, the IGBT combines the advantages of high current-carrying capabilities and high blocking voltages of a bipolar transistor with the capacitive, low power control of a MOSFET. Figure 3 depicts how a MOSFET and a bipolar transistor combined lead to the IGBT.

Figure 3: Conceptual structure of an IGBT showing the MOSFET that makes up the insulated gate and the bipolar transistor structure that is the power handling section. (Image source: Infineon Technologies)

Figure 3: Conceptual structure of an IGBT showing the MOSFET that makes up the insulated gate and the bipolar transistor structure that is the power handling section. (Image source: Infineon Technologies)

The fundamental operation of an IGBT is simple: A positive voltage UGE from gate (G, in Figure 3) to emitter (E) turns on the MOSFET. Then, the voltage connected to the collector (C) can drive the base current through the bipolar transistor and the MOSFET; the bipolar transistor turns on and the load current can flow. A voltage UGE ≤ 0 volts turns off the MOSFET, the base current is interrupted, and the bipolar transistor turns off as well.

While simple in concept, developing hardware to control an IGBT – a gate driver – can be a complex task due to numerous performance nuances in real devices and circuits. Most of the time it’s not necessary. Semiconductor manufacturers offer suitable gate drivers with a wide variety of functions and capabilities as integrated solutions. Hence the importance of matching IGBT modules with appropriate gate drivers.

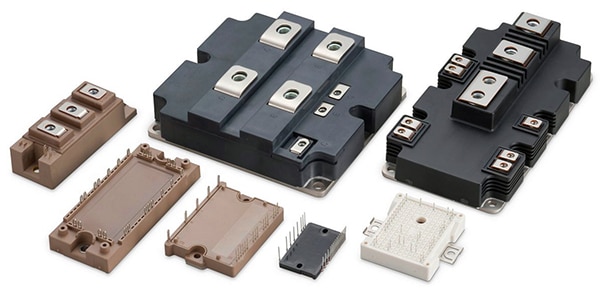

IGBT modules are offered in a wide variety of packages (Figure 4). The largest sizes are rated for 3,300 volts or higher and are designed for use in megawatt installations such as renewable energy systems, uninterruptible power supplies, and very large motor drives. Medium-sized modules are typically rated from 600 to 1700 volts for a variety of applications including electric vehicles, industrial motor drives and solar inverters.

Figure 4: IGBT modules are offered in a wide variety of packages. Typical voltage ratings range from 600 volts to 3,300 volts. (Image source: Fuji Electric)

Figure 4: IGBT modules are offered in a wide variety of packages. Typical voltage ratings range from 600 volts to 3,300 volts. (Image source: Fuji Electric)

The smallest devices are called integrated power modules and are rated for 600 volts and can include built-in gate drivers and other components for motor drives in smaller industrial systems and consumer white goods. IGBTs operate at higher power levels and lower switching frequencies compared with other types of power switching components (Figure 5).

Figure 5: Power range versus switching frequency for common power switching devices (Image source: Infineon Technologies)

Figure 5: Power range versus switching frequency for common power switching devices (Image source: Infineon Technologies)

IGBT module evaluation board for traction inverters

For designers of high voltage traction inverters, NXP Semiconductors offers the FRDMGD3100HBIEVM gate driver power management evaluation board using its MC33GD3100A3EK half-bridge gate driver IC. This evaluation board is specifically designed for use with the FS820R08A6P2BBPSA1 IGBT module from Infineon (Figure 6). It is a complete solution and includes half-bridge gate driver ICs, the DC link capacitor, and the translator board for connection to a PC that provides the control signals. Target applications include:

- Electric vehicle traction motors and high voltage DC/DC converters

- Electric vehicle on-board chargers and external chargers

- Other high voltage AC motor control applications

Figure 6: NXP’s FRDMGD3100HBIEVM gate driver power management evaluation board attached to the FS820R08A6P2BBPSA1 IGBT module from Infineon showing the position of the MC33GD3100A3EK, half-bridge gate driver ICs, the DC link capacitor, and the translator board for connection to a PC that provides the control signals. (Image source: NXP Semiconductors)

Figure 6: NXP’s FRDMGD3100HBIEVM gate driver power management evaluation board attached to the FS820R08A6P2BBPSA1 IGBT module from Infineon showing the position of the MC33GD3100A3EK, half-bridge gate driver ICs, the DC link capacitor, and the translator board for connection to a PC that provides the control signals. (Image source: NXP Semiconductors)

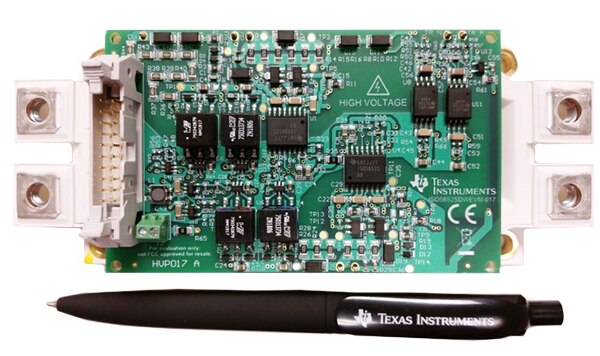

Driver for 150 mm x 62 mm x 17 mm IGBT modules

For designers of motor drives, solar inverters, HEV and EV chargers, wind turbines, transportation, and uninterruptible power supply systems, Texas Instruments has developed the ISO5852SDWEVM-017 (Figure 7). It is a compact, dual-channel isolated gate driver board providing drive, bias voltages, protection and diagnostics needed for generic half-bridge silicon carbide (SiC) MOSFET and silicon IGBT modules housed in standard 150 mm × 62 mm × 17 mm packages. This TI EVM is based on the ISO5852SDW 5,700 volt rms reinforced isolation driver IC in a SOIC-16DW package with 8.0 mm creepage and clearance. The EVM includes SN6505B-based isolated DC/DC transformer bias supplies.

Figure 7: Texas Instruments’ ISO5852SDWEVM-017 dual-channel isolated gate driver board mounted on top of a 150 mm × 62 mm IGBT module. (Image source: Texas Instruments)

Figure 7: Texas Instruments’ ISO5852SDWEVM-017 dual-channel isolated gate driver board mounted on top of a 150 mm × 62 mm IGBT module. (Image source: Texas Instruments)

Intelligent power module eval boards

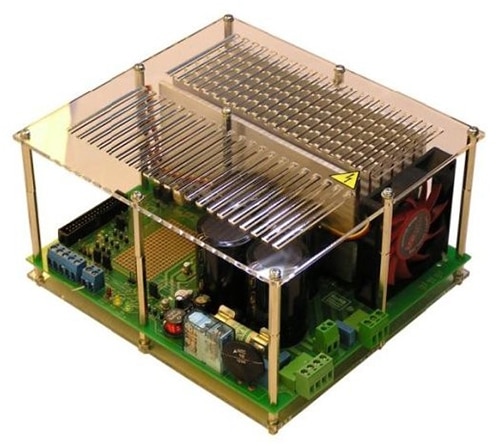

STMicroelectronics offers the STEVAL-IHM028V2 2,000 watt 3-phase motor control evaluation board (Figure 8) featuring the STGIPS20C60 IGBT intelligent power module. The evaluation board is a DC/AC inverter that generates a waveform for driving 3-phase motors such as induction motors or PMSM motors up to 2000 watts in HVAC (air conditioners), white goods and high-end single-phase power tools. Designers can use this EVB to implement FOC designs with three-phase AC motors.

The main section of this EVM is a universal, fully evaluated and populated design consisting of a 3-phase inverter bridge based on the 600 volt IGBT intelligent power module in the SDIP 25L package mounted on a heatsink. The intelligent power module integrates all power IGBT switches with freewheeling diodes together with high-voltage gate drivers. This level of integration saves PCB space and assembly costs and contributes to increased reliability. The board is designed to be compatible with single-phase mains, supplying from 90 to 285 volts AC, and is also compatible with inputs of 125 up to 400 volts DC.

Figure 8: STMicroelectronics STEVAL-IHM028V2 product evaluation board with FOC. This board can be used to evaluate a wide range of applications such as HVAC (air conditioners), white goods and high-end single-phase power tools. (Image source: STMicroelectronics)

Figure 8: STMicroelectronics STEVAL-IHM028V2 product evaluation board with FOC. This board can be used to evaluate a wide range of applications such as HVAC (air conditioners), white goods and high-end single-phase power tools. (Image source: STMicroelectronics)

850 watt eval board handles multiple motor types

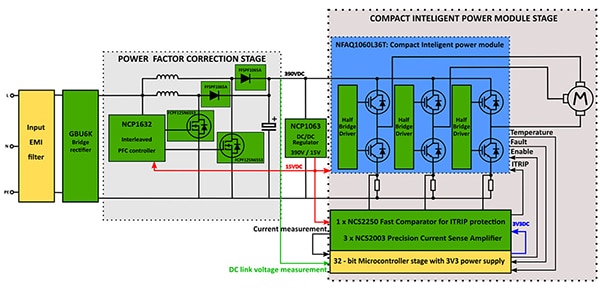

ON Semiconductor offers the SECO-1KW-MCTRL-GEVB evaluation board that enables designers to control different types of motors (AC induction motor, PMSM, BLDC) by using various control algorithms, including FOC, implemented with a microcontroller which can be connected via Arduino Due headers (Figure 9). The board is designed to be used with the Arduino DUE (compatible header) or a similar controller board with an MCU. The board was introduced to support developers during their first steps designing applications with integrated power modules and power factor correction. It is intended for use by designers of industrial pumps and fans, industrial automation systems and consumer appliances.

Figure 9: ON Semiconductor SECO−1KW−MCTRL−GEVB eval board block diagram (Image source: ON Semiconductor)

Figure 9: ON Semiconductor SECO−1KW−MCTRL−GEVB eval board block diagram (Image source: ON Semiconductor)

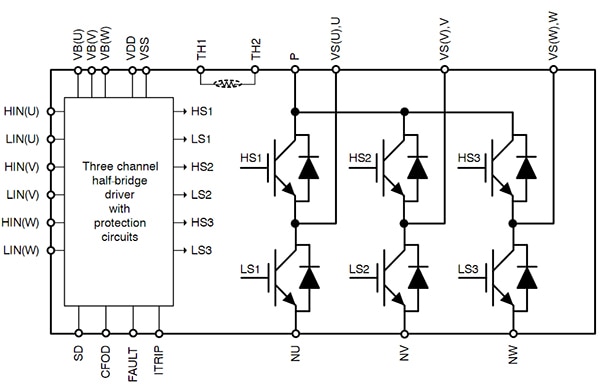

This eval board is based on the NFAQ1060L36T (Figure 10), an integrated inverter power stage consisting of a high voltage driver, six IGBTs and a thermistor, suitable for driving PMSM, BLDC and AC induction motors. The IGBTs are configured in a 3-phase bridge with separate emitter connections to the lower legs for maximum flexibility in the choice of control algorithm. The power stage has a full range of protection functions including cross-conduction protection, external shutdown and undervoltage lockout functions. An internal comparator and reference connected to the overcurrent protection circuit allows the designer to set its protection level.

Figure 10: Functional block diagram of the NFAQ1060L36T power integrated module from ON Semiconductor (Image source: ON Semiconductor)

Figure 10: Functional block diagram of the NFAQ1060L36T power integrated module from ON Semiconductor (Image source: ON Semiconductor)

NFAQ1060L36T power integrated module summary of features:

- Three-phase 10 ampere/600 volt IGBT module with integrated drivers

- Compact 29.6 mm x 18.2 mm dual in line package

- Built-in under voltage protection

- Cross conduction protection

- ITRIP input to shut down all IGBT’s

- Integrated bootstrap diodes and resistors

- Thermistor for substrate temperature measurement

- Shut down pin

- UL1557 certification

Conclusion

Designing custom motor and inverter power electronics using discrete IGBTs to fit specific requirements can be costly in the long term and delay design schedules. Instead, designers can use off-the-shelf IGBT modules which combine multiple power devices into a single package. Such modules support designers’ need to develop compact systems with a minimum of interconnects, thereby simplifying assembly, reducing time-to-market and cost, and improving overall performance.

As shown, designers can use an IGBT module with an appropriate IGBT driver to develop cost effective and compact motor drives and inverters that meet performance and efficiency standards.

Recommended Reading

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.