How to Design for Optimal LED Performance in Architectural Lighting

Contributed By DigiKey's North American Editors

2021-10-12

Traditional architectural lighting (AL) sources—that is, incandescent, halogen, and fluorescent bulbs—are rapidly being replaced in existing, as well as new designs, with illumination based on light-emitting diodes (LEDs). The reasons are clear: apart from regulatory mandates, LED lighting promises much higher efficiency, lower operating costs, reduced thermal loading, much longer installed lifetime (for lower maintenance costs), and a path to smarter management of building functions.

However, using LEDs in a bulb that is a form-and-fit replacement for those long-established lamps is not trivial. New drive circuitry is needed that provides controlled current (not voltage), often with dimming capabilities. In addition, while incandescent bulbs are resistive loads and can run directly from the AC power line, LEDs are different. They do not present a unity power factor—that is, current and voltage are in phase—and their switching regulator drive circuitry is a potential source of electromagnetic interference (EMI). Instead, the driving circuitry must provide and control the required drive current in a way that is optimized for the characteristics of the LED load. The driver may also have to implement power factor correction (PFC), dimming capability, and EMI suppression.

This article looks at various aspects of architectural lighting and the ICs that are enabling LED-based architectural lighting. It then introduces ICs from Diodes Incorporated as examples of their use in actual circuits.

The goals of AL and the challenges of LEDs

AL is the design and use of lighting systems that are embedded inside and outside of a commercial, non-residential structure such as a retail store, office, or warehouse. The objective of architectural lighting design is to balance the art and the science of lighting to create mood, visual interest, and to enhance the experience of a space or place, while still meeting the technical and safety requirements. It does not include impromptu lights that people bring in or rearrange, such as their favorite desk lamp; instead, it is the lighting that “comes with the building,” although it often allows for some flexibility and even rearrangement as short and long-term needs evolve.

In recent years, AL has become a larger and more technology-driven field with added challenges, largely due to the need to conserve energy and to manage lighting’s associated functions and features. As LED-based lighting has become a dominant factor in upgrading AL, the techniques, circuitry, and components that can efficiently drive the LEDs in the AL luminaires (fixtures) have become increasingly important.

Much of the impetus for the transition to LED-based AL comes from multiple regulatory mandates and standards defining various perspectives on efficiency including dimmability, PFC, and EMI generation, among other factors. The specifics of these highly complicated and lengthy requirements differ among global regions, countries, and even states within the United States.

Among the important regulatory requirements in the U.S. are federal Energy Star standards and the Title 24 California Building Standards Code, which is stricter than Energy Star. Among its many other considerations, Title 24 requires:

- Occupancy sensors for automatic on/off of illumination loads

- LED drivers with dimming capability

- Higher efficiency as measured by useful lumens of output per watt of input power

- Smart Connected Lighting (SCL) supporting wireless control of individual and grouped lamps via Bluetooth, Zigbee, or DALI/IEC 62386, with system standby power under 200 milliwatts (mW)

- LED output-current ripple below 30% to avoid annoying and distracting flicker

- PFC of 0.9 or higher at defined higher power

- Total harmonic distortion (THD) below 20% to minimize wasted power due to non-resistive loads

A note about dimming rate and flicker: although the human eye is generally insensitive to flicker above 100 Hz, there is an associated phenomenon, sometimes called “eflicker,” which occurs when pulse width modulation (PWM) is used to dim the LEDs, either for brightness or color control. In PWM, the LED is turned off for short periods of time (hundreds of microseconds) at a high rate. This dimming rate can interact with scanning and refresh rates of basic LED readouts, display screens, security cameras, and other optical imaging devices. For this reason, the LED refresh rate should be much higher than the rate at which the eye itself is sensitive, and this is the case for components from Diodes Incorporated.

Go beyond chips to chipsets

Meeting the multiple energy-related requirements is a design challenge that requires juggling conflicting approaches, as there are inevitable interactions and compromises among the “best” solutions to each objective. Individual ICs are available that are optimized to address specific aspects of the problem, but a complete solution requires ensuring that these ICs work together in harmony and reinforce each other, rather than counter.

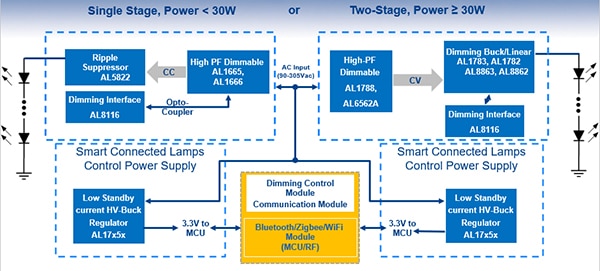

For this reason, it often makes sense to look at ICs from a single vendor and any associated chipset—verified circuits that group these ICs—that the vendor has put together. This provides designers with a tested topology and makes a good starting point. For LED-based AL, Diodes Incorporated offers suggested chipsets in two groups, one supporting lower power situations (under 30 W), and another for higher power installations (above 30 watts), with the former typically being used indoors and the latter outdoors.

The block diagram in Figure 1 shows how the three basic ICs that comprise the chipset for <30-watt power applications—a dimmable LED controller, a ripple suppressor, and a dimming-signal interface controller—interact with each other, providing the needed core functionality.

Figure 1: Advanced ICs—a dimmable LED controller, a ripple suppressor, and a dimming-signal interface controller—form the core of a design for <30-watt architectural lighting. (Image source: Diodes Incorporated)

Figure 1: Advanced ICs—a dimmable LED controller, a ripple suppressor, and a dimming-signal interface controller—form the core of a design for <30-watt architectural lighting. (Image source: Diodes Incorporated)

Looking at the three ICs individually, the AL1666S-13 high-performance dimmable LED controller operates from a wide input voltage range of 85 volts AC (VAC) to 305 VAC, while offering a PFC greater than 0.9 and THD below 10%. It supports 0-to-10 volt analog dimming over a 5% to 100% span and works with all ANSI-standard dimmers; for the non-analog PWM dimming, the range is 1% to 100% at 1 kilohertz (kHz). For consistency in performance, it offers tight LED-current line regulation of better than ±2%, and LED-current load regulation of better than ±2% from full load down to half load.

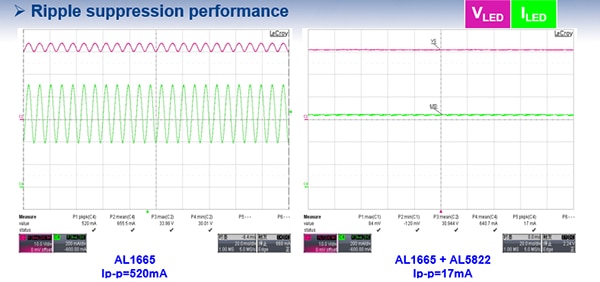

Next, the AL5822W6-7 is an adaptive 100/120 Hz LED-current ripple suppressor in an SOT-23-6 package. It meets the difficult challenge of minimizing current ripple to meet increasingly strict standards. Further, as it is the device that interfaces with the LEDs, it is necessary that it incorporate protection against short circuits, overcurrent, and overtemperature while supporting hot-bulb operation for when the circuit and bulb are inserted into a “live” socket. It can provide dramatic ripple reduction, bringing it down to just a few percent of the original value, as demonstrated with some basic numbers. For example, when used with the AL1665S-13 high-performance dimmable LED controller—a close sibling of the AL1666S-13—current ripple is about 520 milliamperes (mA) peak-to-peak, but decreases to just 17 mA when paired with the AL5822 (Figure 2).

Figure 2: Adding the AL1665S-13 high-performance dimmable LED controller to the design reduces ripple from 520 mA peak-to-peak to just 17 mA. (Image source: Diodes Incorporated)

Figure 2: Adding the AL1665S-13 high-performance dimmable LED controller to the design reduces ripple from 520 mA peak-to-peak to just 17 mA. (Image source: Diodes Incorporated)

Finally, there’s the AL8116W6-7, a flexible 0-to-10 volt dimming-signal interface controller. It operates from a wide VCC range of 10 to 56 volts, which can be derived from the output voltage of an auxiliary winding, a power rail, or the LED chain voltage. It supports PWM dimming over a 0.2 kHz to 10 kHz range using 0-to-10 volt control, and potentiometer (resistive) dimming (0 to 100 kilohms (kΩ)). It converts dimming control to the PWM output required by the system while providing a simple cross-isolation-barrier dimming solution. It also offers a ±2.5% PWM output duty cycle for an accurate dimming curve, critical in multi-LED installations.

Of course, high-level block diagrams can be deceptive with respect to showing the total bill of materials (BOM), including passive components, discrete active components, and other ICs. Therefore, it’s important to look at the actual schematic to understand what the complete circuit requires, as this affects packaging, production, and cost.

For the <30 watt chipset of Figure 1, the schematic diagram shown in Figure 3 below shows how few components are actually required. (Transformer T1 and the optocoupler are needed for galvanic isolation between primary and secondary sides.)

Figure 3: The details provided by a schematic diagram of the high-level block diagram shown in Figure 1 show that only a few additional components are required in the complete design. (Image source: Diodes Incorporated)

Figure 3: The details provided by a schematic diagram of the high-level block diagram shown in Figure 1 show that only a few additional components are required in the complete design. (Image source: Diodes Incorporated)

Since all switching-based power circuits have real-world subtleties that a schematic diagram alone cannot reveal, an evaluation board is an asset for speeding design validation and verification. The AL1666+AL8116+AL5822EV1 is an evaluation board that uses the three named ICs to provide a 0-to-10 volt dimmable, high PFC, single-stage flyback LED driver (Figure 4). It provides a constant output current of 1200 mA over a voltage range of 25 to 50 volts from an input voltage of 90 VAC to 305 VAC.

Figure 4: To accelerate project completion, the AL1666+AL8116+AL5822EV1 evaluation board (top and bottom) facilitates deeper understanding of the dimmable LED driver circuit operation utilizing the AL1666 primary-side controller, the AL8116 secondary-side dimming interface IC, and the AL5822 LED current ripple suppressor. (Image source: Diodes Incorporated)

Figure 4: To accelerate project completion, the AL1666+AL8116+AL5822EV1 evaluation board (top and bottom) facilitates deeper understanding of the dimmable LED driver circuit operation utilizing the AL1666 primary-side controller, the AL8116 secondary-side dimming interface IC, and the AL5822 LED current ripple suppressor. (Image source: Diodes Incorporated)

Size matters for backward compatibility

Why are small size and a short BOM important, beyond the customary “smaller is better” rationale? It’s partially an issue of backward compatibility with existing lamps (bulbs) when using LED-driving ICs individually or in groups.

For example, while there are many different AL lamp form factors in common use, one that is especially widespread is the MR16 used in residential and commercial settings for directional lighting (Figure 5). Bulbs with halogen light sources in this form factor have been among the first choices for standard AL illumination for many years.

Figure 5: The MR16 bulb form factor and size using halogen as the light source is widely used in AL installations. (Image source: Wikipedia; W.W. Grainger, Inc.)

Figure 5: The MR16 bulb form factor and size using halogen as the light source is widely used in AL installations. (Image source: Wikipedia; W.W. Grainger, Inc.)

The MR16 is 2 inches in diameter at its largest circumference. The “MR” stands for multifaceted reflector, which is what controls the direction and spread of the light it casts. This bulb usually (but not always) operates from a 12 volt AC line, which is generally provided via a line-voltage step-down transformer.

A small halogen MR16 requires 20 watts and has a 2,000 to 6,000 hour lifetime. In contrast, the LED equivalent requires only a few watts and has a lifetime on the order of 100,000 hours. As AL transitions to LED-based light sources, it’s important to be able to include needed circuitry in this package to provide form-and-fit bulbs for the huge replacement aftermarket, as well as for new AL design-ins.

Meeting higher power needs

For LED lamp driving above 30 watts (which equates to about 3 amperes (A) of LED current drive), such as outdoor applications, a two-stage topology may be preferred to the single-stage approach, although their control and communications modules can be the same (Figure 6).

Figure 6: Higher power LED lighting designs (above 30 watts) make use of a two-stage topology (right) in contrast to the single-stage approach of lower power designs (left), but their “smart” interface can be the same. (Image source: Diodes Incorporated)

Figure 6: Higher power LED lighting designs (above 30 watts) make use of a two-stage topology (right) in contrast to the single-stage approach of lower power designs (left), but their “smart” interface can be the same. (Image source: Diodes Incorporated)

Once again, the circuit schematic—in this case for that of the higher power LED lighting design solution—provides more detailed insight (Figure 7).

Figure 7: The schematic diagram again shows the relatively high level of integration offered by this higher power solution. (Image source: Diodes Incorporated)

Figure 7: The schematic diagram again shows the relatively high level of integration offered by this higher power solution. (Image source: Diodes Incorporated)

As in the lower power design, three ICs are at the core of this implementation. First is the AL1788W6-7, a primary-side controller that supports buck (step down) and flyback topologies that require no optocoupler, while its quasi-resonant (QR) operation with “valley-on function” provides low switching loss. Power factor is better than 0.9 while THD is below 15%, and standby power of below 200 mW (for use during the day when lights are off, for example) adds to the overall efficiency.

Next, the AL17050WT-7 is a universal AC non-isolated buck regulator that provides accurate constant voltage (CV) control with extremely low standby power in a tiny SOT-25 package. It integrates a 500 volt MOSFET and works with a single-winding inductor, resulting in simpler external components and a lower cost BOM. Due to its electrical role and position in the overall topology, the device includes multiple production “layers”, including overtemperature protection, VCC undervoltage lockout, output short-circuit protection, overload protection, and open-loop protection.

Finally, there’s the AL8843SP-13, a 1 megahertz (MHz) step-down regulator and analog LED driver with PWM dimming, capable of delivering output current up to 3 A, which is adjustable via an external resistor. It operates from a wide input voltage of 4.5 to 40 volts and features ±4% current-sense accuracy for superior channel-channel matching in multi-LED designs.

The AL8843SP-13 integrates the power switch and a high-side output current-sensing circuit; depending on supply voltage and external components, the converter can provide up to 60 watts of output power with efficiency up to 97%. The important dimming function can be implemented by applying an external control signal to a single package pin that accepts either a DC voltage or a PWM signal. This thermally enhanced SO-8EP-packaged device also includes protection against an open or shorted LED and an open or shorted current-sense resistor, among its other protection modes.

As with the lower power LED driving arrangement, an evaluation board for the higher power solution can greatly reduce the hours needed to better understand a full design-in situation and so move the project along more effectively. For the AL8843SP-13 step-down LED driver—the most challenging component of the higher power design—Diodes Incorporated offers the AL8843EV1 evaluation board (Figure 8).

Figure 8: Users of the AL8843SP-13 will benefit from the basic AL8843EV1 evaluation board, which focuses entirely on the single step-down regulator and 3 A analog LED driver IC with PWM dimming. (Image source: Diodes Incorporated)

Figure 8: Users of the AL8843SP-13 will benefit from the basic AL8843EV1 evaluation board, which focuses entirely on the single step-down regulator and 3 A analog LED driver IC with PWM dimming. (Image source: Diodes Incorporated)

The AL8843EV1 evaluation board allows for basic exercise of the IC without interaction or interference due to other active components.

Then there’s “connected lighting”

One of the other enhancements that is both practical and desirable with modern LED-based lighting is the opportunity to implement “smart connected lighting” (SCL), often described simply as “connected lighting”. Among its various attributes, it allows for lamps to be controlled as a group as well as individually within a group, via a connectivity standard.

What are the benefits of SCL? From a higher-level system perspective—and perhaps even with some speculation and exaggeration—a connected lighting infrastructure becomes an investment in a building-wide connectivity grid. The data flowing through this infrastructure allows building managers to integrate, automate, and extend the life of core building systems, lower their operating costs, increase performance, and decrease downtime.

Some analysts maintain that the benefits of connected lighting go far beyond just illumination. For example, Szymon Slupik, CTO and founder of Silvair, notes, “The value of additional services enabled by smart lighting is seven to ten times more valuable than the lighting controls and energy savings themselves.”

SCL lamps are often in a passive “listening” state for long periods, so standby power consumption is a key parameter of concern for designers, and maximum values are specified in the various regulatory mandates. The controllers and regulators from Diodes Incorporated are designed with standby power ratings below the allowed values. They also work with dimming control/communication models supporting various interface standards including Bluetooth, Zigbee, and Wi-Fi.

One factor that will drive the installation of connected lighting is the development of industry-wide standards ensuring interoperability of SCL components from different vendors. For example, the Bluetooth Special Interest Group (SIG) has worked with the lighting industry to develop a Bluetooth mesh standard optimized for creating applicable large-scale device networks. Further, the Bluetooth SIG and the DALI Alliance collaborated to create a standardized interface that will enable D4i certified luminaires and DALI-2 devices to be deployed in Bluetooth-based mesh lighting control networks (D4i is the DALI standard for intelligent, IoT-ready luminaires). Via this interface, data can flow unimpeded between sensor-rich luminaires and lighting controls, and even to other building management systems.

Conclusion

Smart LED-based architectural lighting is improving the energy efficiency of illumination systems in commercial buildings. It is also a critical element for enabling long-range potential gains in overall building performance. Controller, regulator, and LED driver ICs from Diodes Incorporated that are focused and optimized for LED-based AL, are among the key building blocks needed to successfully translate the potential benefits of these advanced AL possibilities into a powerful, versatile, and cost-effective reality.

Reference

DALI Alliance, D4i – the DALI standard for intelligent, IoT-ready luminaires

Further reading

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.